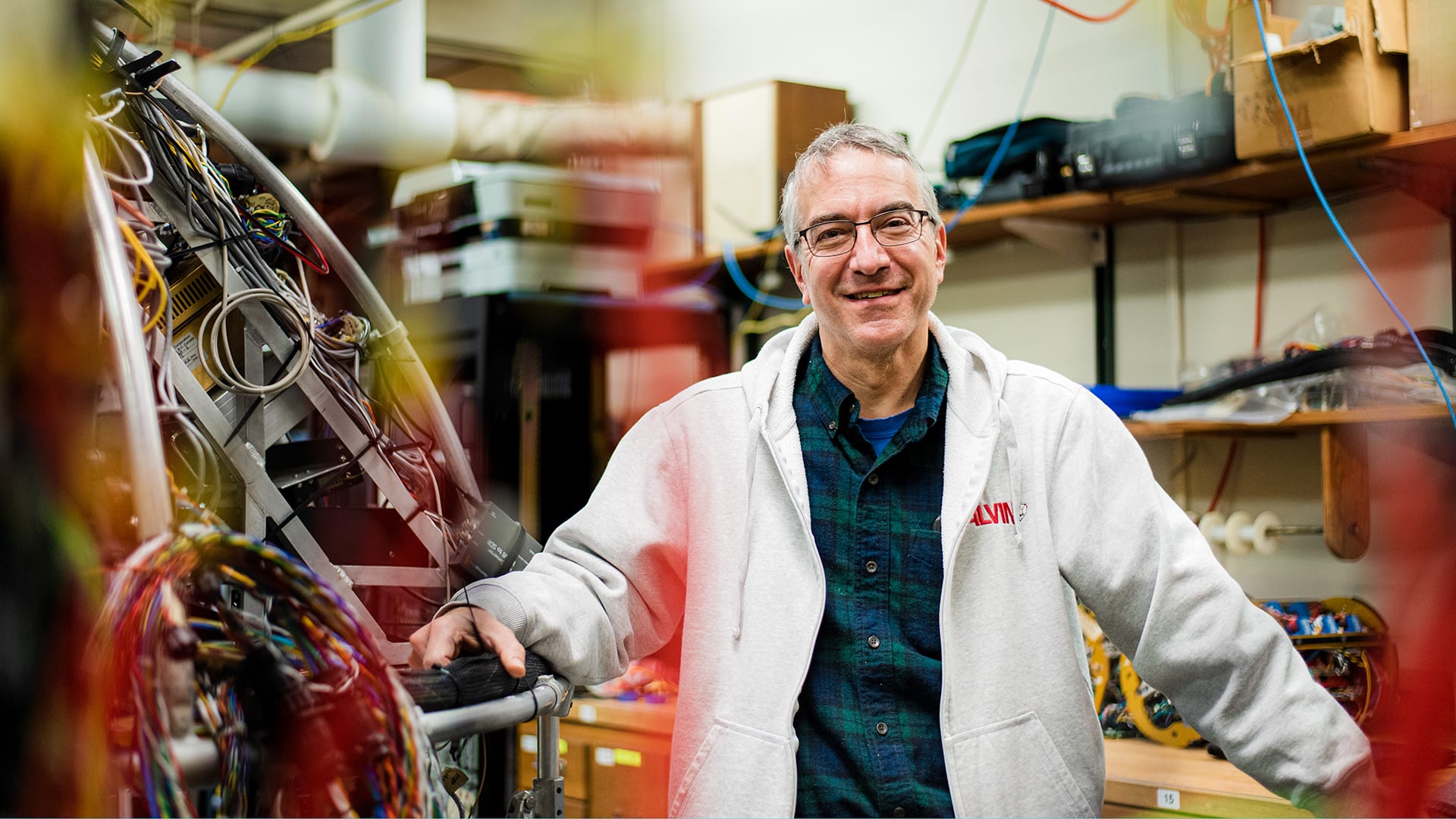

Meet the Alvin 6500 Team: Lane Abrams

Senior Electrical Engineer Lane Abrams moves from the drawing board to the deep ocean

By Hannah Piecuch | January 6, 2021

In 1991, Abrams was working as an electrical engineer at Bell Labs in New Jersey, when he saw a help wanted ad in the Boston Globe for the Alvin Group at Woods Hole Oceanographic Institution. Thirty years later, he is the senior engineer who oversees shore-side electrical support for the sub. Abrams’ group reconfigured the electrical systems during the last overhaul, anticipating that the group was set to extend its range from 4,500 to 6,500 meters.

Lane is a quiet, meticulous engineer who takes his job of overseeing the sub’s electronics very seriously, applying painstaking care to each step of his seemingly endless tasks. He took time to speak to Oceanus about what he’s doing in the current overhaul period and how he approaches his job.

This is the second interview in a multi-part series with members of the Alvin Group.

Oceanus: What do you do for the Alvin Group?

Lane: I support the operations crew while they are at sea. During a research cruise, they can’t run to the store and buy a part. I can. And I can make sure it is waiting for them at the dock when they land at the next port stop. Every five years we switch gears for overhauls.

Oceanus: How does your work look different during an overhaul year?

Lane: This overhaul doesn’t have as many electronic changes as the last one, when we remade the whole electrical plant for the submarine. This time we’re updating individual components such as electrical motors for pumps and the electrical drives that make the motors go. We’ve purposely built Alvin so that the electrical system is a small part of what is required to keep people safe. There’s no electricity required to keep people alive in the sub.

A lot of my time right now is managing the work flow and making sure that our electronic controls will work with the new mechanical and hydraulic changes. I keep track of the status of these projects, keep jobs rolling along, find the right people to do stuff. It’s good for us to have a top-level view to make sure that everything is going to work together.

Oceanus: Is there any part of this overhaul that you’re particularly excited about?

Lane: Being a design engineer, designing new stuff is really fun. It’s very nice to start with a blank piece of paper and a pencil and draw something out. You build mock-ups and tests and prototypes, and then you make a real one and you try it out. If it doesn’t work, then you try again and fix the problems. Eventually it ends up in the submarine and they take it to the bottom of the ocean. That’s really rewarding.

Oceanus: Is there a project that you’ve gone back to the drawing board with this time?

Lane: There are a couple. They are kind of all around me here in my office.

Right now I am rewriting the maintenance procedure for the hull penetrators. Other than the hatch and windows, the openings for penetrators are the only holes in the personnel sphere. The penetrators are housings that hold the wiring that allows the pilot to control the sub from inside. They have to hold back a lot of pressure.

These penetrators were designed for the new hull, which was forged during the last overhaul. During any overhaul, every item gets maintenance of some sort or another. Sometimes we just wipe it down, inspect it, put it in a bag, put it on a shelf and it is ready to go. Other times we take it apart, replace some parts, put it back together, make adjustments, and then it is ready to go. Penetrators are more in the latter group. We have a certain amount of maintenance that happens with them regularly. But in overhauls they go through a deeper maintenance.

As it turns out, the procedures we had for regular maintenance at sea weren’t quite right. So, in preparing for this overhaul, I always knew that this had to be redone. And so I have these mock-ups and I sat up here and I did the procedure, and thought, “That ain’t right. I’ve gotta fix this.” So that’s been a big effort, to get the maintenance procedure right.

Oceanus: You said that your day to day hasn’t changed much – but what kinds of things have you accomplished in 30 years that might surprise your younger self?

Lane: What I have found surprising is how fast the years have gone by, how much we have accomplished in that time as a team, how hard it sometimes was, but it was always rewarding. And how much fun this has been.