Long Core Sea Trials

- Scientists and engineers headed out aboard the research vessel Knorr in September 2007 to try the new long core system at sea for the first time. (Woods Hole Oceanographic Institution)

- The core barrel, measuring 45 meters (150 feet) long, is stowed on brackets along the ship's starboard side. Three computer-controlled davits then lift the core off the brackets and move it outboard and clear of the ship's hull. (Woods Hole Oceanographic Institution)

- The long corer is lowered to vertical by the davits while held captive by a pivoting grapple. The grapple then rotates the corer to the center of the ship's stern (rear), where it is lowered to the seafloor. (Woods Hole Oceanographic Institution)

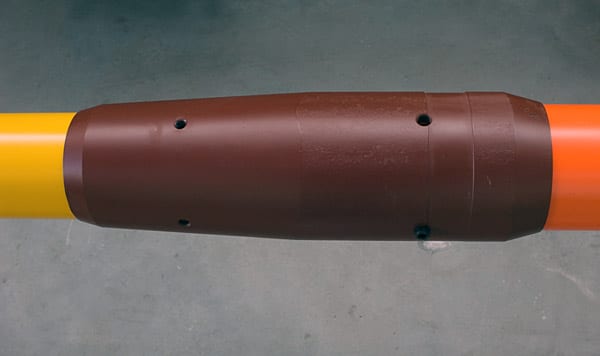

- The core barrel is made of individual high-strength steel sections (yellow and orange) joined by couplings (burgundy). To resist bending, barrel sections at the top have the thickest walls (1 1/8 inches), tapering down to 3/8 of an inch at the bottom. (Tom Kleindinst, Woods Hole Oceanographic Institution)

- Engineers blended two types of synthetic rope to make a 4.3-mile-long, 2-inch-diameter line that has a breaking strength of 355,000 pounds. Its superior strength minimizes elongation at full ocean depths, allowing cores to be recovered without disturbance to their stratigraphy (the layering of the sediments). (Tom Kleindinst, Woods Hole Oceanographic Institution)

- A large, disk-shaped acoustic modem provides two-way communications. It relays undersea data from the corer to the ship (such as how far the corer is from the seafloor). It also receives and executes commands from the ship (including when to release the corer to plunge into the seafloor to collect sediment). (Woods Hole Oceanographic Institution)

- At the first phase of recovery, after the core system has been winched back from the seafloor, the acoustic release module returns first, now separated from the long core. The module must be recovered and secured on deck before the long core surfaces. (Woods Hole Oceanographic Institution)

- The core cutter, with a small amount of "extra-recovered" sediment protruding from the sharp cutting edge, surfaces during the last stage of retrieval of the long core system. (Woods Hole Oceanographic Institution)

- Cores are split in half and taken back to the WHOI Seafloor Sediment Lab, where scientists such as Candace Major analyze them to reconstruct a history of past ocean and climate conditions on Earth. (Tom Kleindinst, Woods Hole Oceanographic Institution)

- Sediments contain evidence of past ocean and climate conditions. They accumulate on the seafloor in layers, offering a chronology of when the conditions occurred. (Tom Kleindinst, Woods Hole Oceanographic Institution)

- WHOI research special Jim Broda (left) and Bill Curry, director of the WHOI Ocean and Climate Institute, return to Woods Hole after the successful sea trials aboard Knorr. The two spearheaded development of the new long corer system. (Tom Kleindinst, Woods Hole Oceanographic Institution)

- To celebrate the testing of the new long core system, Woods Hole artist Joan Lederman created a urn that was "signed" by cruise participants onboard Knorr and then fired. Lederman is known for her singular pottery, which is glazed with seafloor "muds," given to her by WHOI seagoers. She donated the urn to WHOI. "I wanted to salute those who calculate risks, fund experiments, and put their skills on the line, apply all intelligence to implementation, and then accept the outcomes," she said. (Joan Lederman)

Image and Visual Licensing

WHOI copyright digital assets (stills and video) contained on this website can be licensed for non-commercial use upon request and approval. Please contact WHOI Digital Assets at images@whoi.edu or (508) 289-2647.