Sample

preparation task #3, by E. Sichel on Feb. 1, 2002.

Shown

above are 20 pieces of stainless steel, 0.031-inch X 1.5-inch

X 6.0-inch. The adhesives were applied on a 1.5-inch by 1.5-inch

overlap area and the adhesive bond will be tested in tension

mode. The stainless steel was cleaned with Scotch-Brite soap

pads in hot water, rinsed, and dried. The control samples

were cured in air. The experimental samples were prepared

in air on the bench. They were left to dry for 15 minutes,

and then immersed in a tray of seawater and stored, in the

covered tray, in the refrigerator at 34 degrees F.

The

adhesives used in this test of strength of the adhesive bond

are:

Aquamend,

two-part epoxy

PSI-326,

two-part epoxy

3M

Co. Marine sealant 5200

3M

Co. FastCure 5200

3M

Co. FastCure 4200

The strength of the adhesive bonds of the

life-tested samples in seawater will be measured by Prof.

Ucci's engineering students at Bristol Community College.

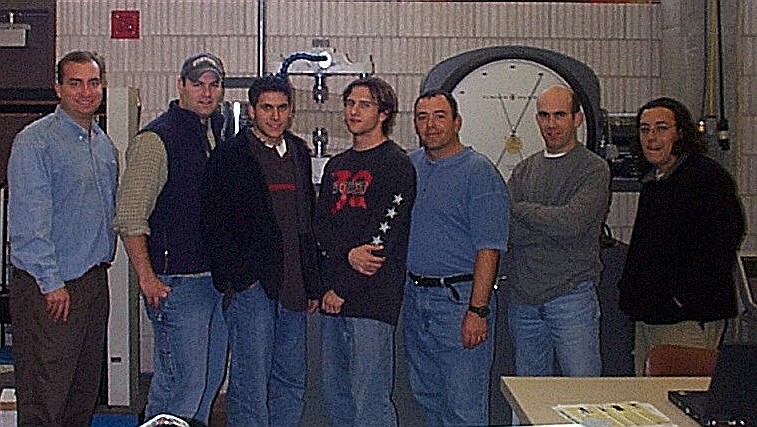

Shown above are Prof. Ucci (left) and his engineering students

in their laboratory.

Inspection

Report

On

Feb. 19, 2001 the samples were removed from the refrigerator

after 18 days at 34 degrees F. The samples were left in

their sample trays in seawater. They were then stored at

about 45 degrees F in their seawater trays for 24 hours

for delivery to Prof. Ucci on Feb. 20, 2002. |